Nuclear Industrial Directory of Japan

5-7-12 Takeshima, Nishiyodogawa-ku, Osaka 555-0011, Japan

Having pursued ideal quality and conducted extensive research and development as a specialized manufacturer of high-function carbon, in 1974, Toyo Tanso became the first company in the world to successfully mass produce isotropic graphite. Since that time, our products have been supporting domestic life and industrial infrastructure in various fields.

Carbon applications continue to expand from electronics and general industry into cutting-edge fields such as nuclear power and aerospace. To keep pace with this trend, we supply world-class products that leverage our know-how in areas such as manufacturing ultra-large materials, precision processing at the micron level, and providing advanced functionality and high-added value to suit different applications.

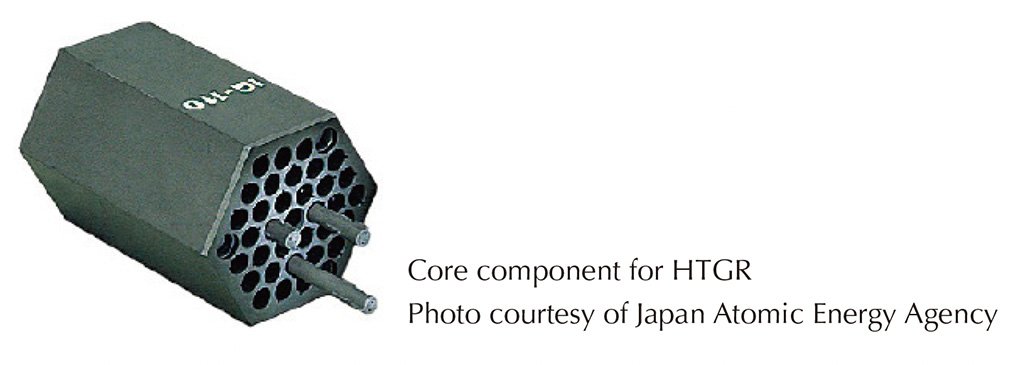

Our IG-110 is the world’s only graphite material employed as components for high-temperature gascooled reactors (HTGR).

Graphite is very effective at slowing down fast neutrons to thermal neutrons, but is not very effective at absorbing neutrons. Thanks to its excellent thermal and mechanical properties at high temperatures, graphite is additionally used as a moderator and reflector in components in HTGRs.

Of the various graphite materials available, Toyo Tanso’s fine-grained isotropic graphite, IG-110, provides excellent thermal durability, sufficient strength and highly consistent quality.

Due to the fact that it is availability of a large amount of outstanding data related to neutron irradiation damage, IG-110 is also currently the only graphite material employed in the world’s three existing HTGRs.

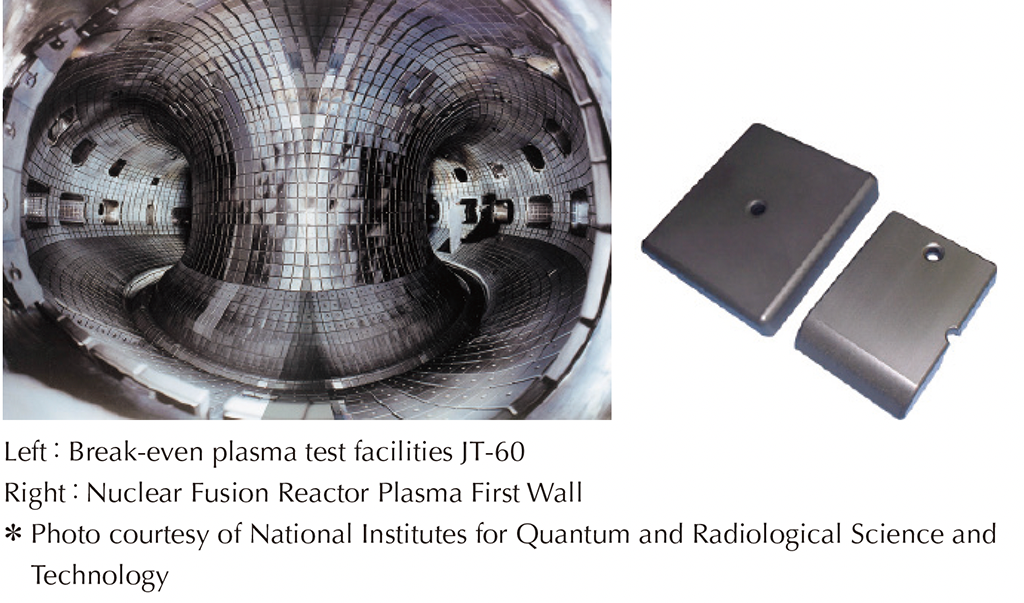

CX-2002U (C/C composite) and IG-430U (isotropic graphite) are exceptional graphite materials that are capable of contributing to early practical applications of nuclear fusion energy ─ considered by many as the energy of the future.

CX-2002U is a high thermal conductivity material made from carbon felt infiltrated with pyrolytic carbon via chemical vapor infiltration (CVI). It is a special material developed for use in diverters in nuclear fusion reactors, which require special heat-removal characteristics for plasma and ions/electron beam.

G-430U is a type of isotropic graphite developed to provide higher density, strength, and thermal conductivity than IG-110, which has been used successfully in HTGRs. It is mainly used in the first walls of plasma facings exposed to low thermal loads.