Nuclear Industrial Directory of Japan

1-1-1, Shinsuna, Koto-ku, Tokyo 136-0075, Japan

With yearly sales of $10 billion, 20 overseas offices, the largest construction R&D laboratory in the world and over 1,000 architects in our design department, Takenaka offers comprehensive services worldwide across the entire spectrum of space creation from site location and planning to design and construction as well as postcompletion services such as building maintenance.

We became the first construction company to win the Deming Prize in 1979 and again the first in the industry to win the Nippon Quality Control Medal in 1992, both in recognition of our efforts in Total Quality Management.

At Takenaka, we strive to consistently improve the quality of our works to ensure building owners that orders placed with us will be fulfilled with the utmost confidence, security, satisfaction and pride throughout the contract period and beyond.

Takenaka has been carrying out construction works for various kinds of nuclear power plants such as BWR and PWR in Japan since the early 1960s.

In Japan since September 2013, all nuclear power plants have suspended their operation to re-evaluate its safety and, electric power companies have to obtain the approval for restarting operation from the Nuclear Regulation Authority.

Takenaka is implementing the structural analysis for mainly earthquakes and tsunamis to ensure safety measurement during reviewing design for the nuclear power plants constructed by Takenaka in the past.

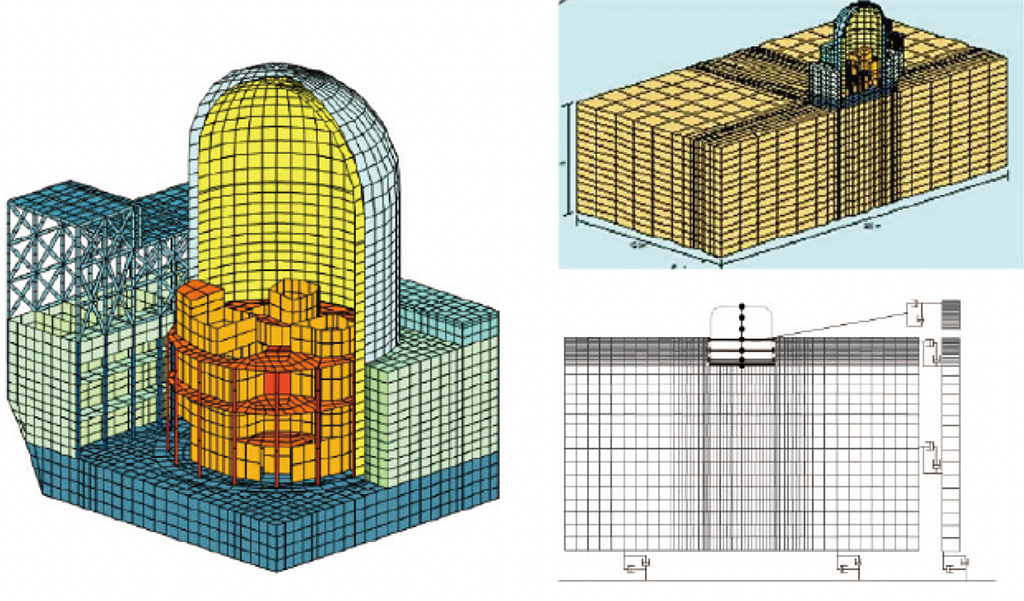

3D FEM model of reactor building with PWR is shown as left-side below. Evaluation for soil-structure interaction by 3D FEM model is shown as below and also with analysis by 2D FEM model.

We have completed new structure frame over the Unit 4 Reactor for the purpose of removing spent fuel rods left in the storage pool at the Unit 4 Reactor.

The condition of radiation dose around Unit 4 is not as severe as Unit 1, 2 and 3. People wearing protection masks have been able to work carefully for a short period of time at the Unit 4 Reactor building. On the contrary, the remote machines have been used to replace human workers at the Unit 1, 2 and 3 Reactor buildings.

Firstly, we cleaned up around Unit 4 as preparation work. Secondly, we removed broken pieces over the operating floor which is located 30 meters above the ground. Finally, we constructed a new structure frame which has been overhung 30 meters without interfering existing objects on the south side of the Unit 4 Reactor building.

A fuel handling machine and a 100-ton overhead crane were installed on the new structural frame. The fuel handling machine picks up the spent fuel rods and inserts those into the cask in the storage pool at 30 meters high. Then the cask contained by spent fuel rods is taken out from the pool and lifted down to the ground.

The design for this structure has resulted in large and heavy size structural members. For example, the concrete foundations are 4 meters thick and the columns and girders are steel square tube with section of 3 meters.

Those columns and girders were effective in shielding steel workers against radiation exposure because steel workers were staying and tightening bolt sets in steel square tube with section of 3 meters.

This construction work has been completed successfully by Takenaka Joint Venture in March 2014, then the removal of spent fuel rods from the Unit 4 Reactor building has been completed in December 2014.