Nuclear Industrial Directory of Japan

Urbannet Uchisaiwaicho Building, 1-1-13 Shimbashi, Minato-ku, Tokyo 105-8681 Japan

Nikkeikin Aluminium Core Technology Co., Ltd.(Nikkeikin ACT) was established in October 2002 and is a 100% owned subsidiary of Nippon Light Metal (NLM) Holdings Company, Ltd. Nikkeikin ACT specializes in manufacturing aluminum extrusion and aluminum processed products and is ISO 9001 and ISO 14001 certified.

Nikkeikin ACT has a diverse and global employee base comprising around 1,150 members, and has created and provided high quality products that have been used by the nuclear industry, construction industry, transport industry and many more.

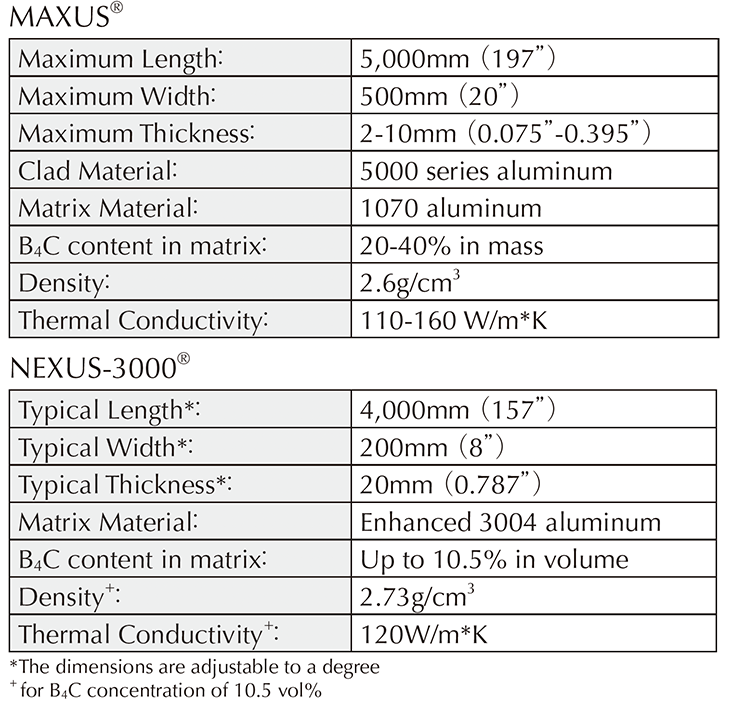

Nikkeikin ACT’s main product for the spent nuclear fuel industry is MAXUS®. MAXUS® is a borated aluminum neutron absorber Metal Matrix Composite(MMC) material used in spent nuclear fuel dry storage / transportation casks as well as spent nuclear fuel pool racks.

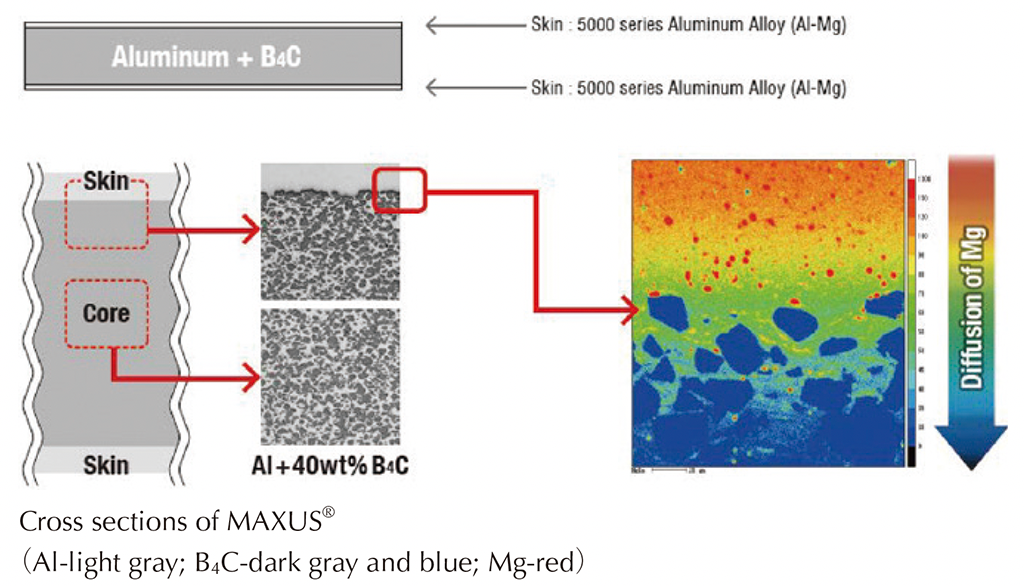

MAXUS® consists of a sandwich structure with highly corrosion resistant aluminum cladding and boron carbide powder (B4C) uniformly distributed within a highpurity aluminum matrix.

The advanced manufacturing process of MAXUS® also allows for strong bonding between the clad and the core through the diffusion of magnesium from the skin’s aluminum alloy. With MAXUS®, Nikkeikin ACT has realized an unprecedented high performance material that meets customers’ expectations.

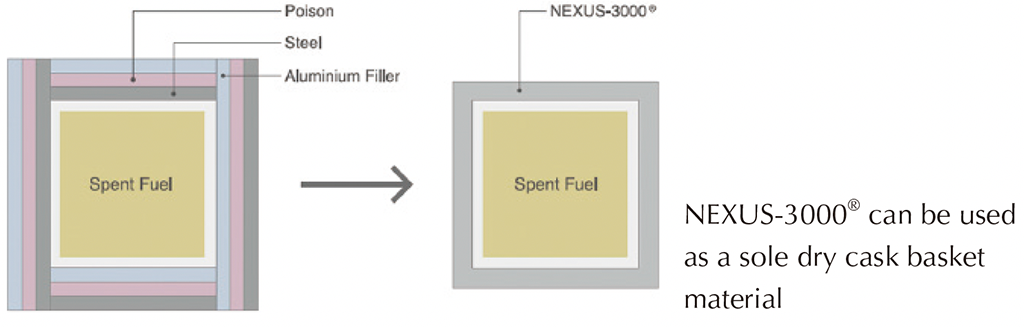

Nikkeikin ACT has also developed an extruded borated aluminum MMC called NEXUS-3000R that has the neutron absorption, strength and thermal conductivity to meet dry cask needs. It can be used solely in dry cask baskets instead of using multiple materials.

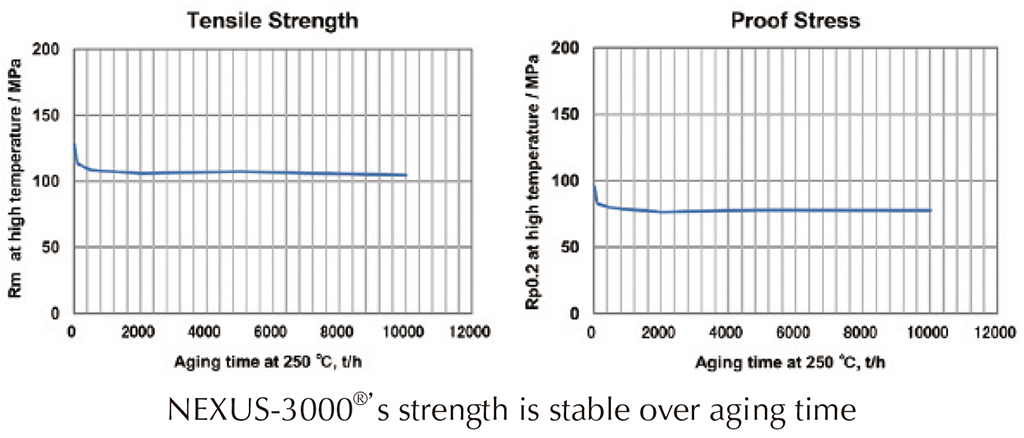

NEXUS-3000(R) comprises of B4C in an enhanced 3004 aluminum alloy matrix (Al-Mn-Mg alloy) that allows NEXUS-3000(R) strength to be stable over aging time.