Nuclear Industrial Directory of Japan

Tokyo Head Office: 1-1, Nishi-Shinagawa 1-chome, Shinagawa-ku, Tokyo, 141-0033, Japan

Kobe Head Office: 2-4, Wakinohama-kaigandori 2-chome, Chuo-ku, Kobe, Hyogo, 651-8585, Japan

The Kobe Steel Group, a global enterprise built around Kobe Steel, Ltd., is engaged in a wide range of fields, with its major businesses in materials (iron and steel, welding, aluminum and copper products), industrial and construction machinery, as well as engineering in the field of natural resources and environmental solutions.

While various energy sources have been reconsidered as countermeasures for global warming, nuclear energy plays a significant role in today’s energy supply with ever higher levels of reliability and safety.

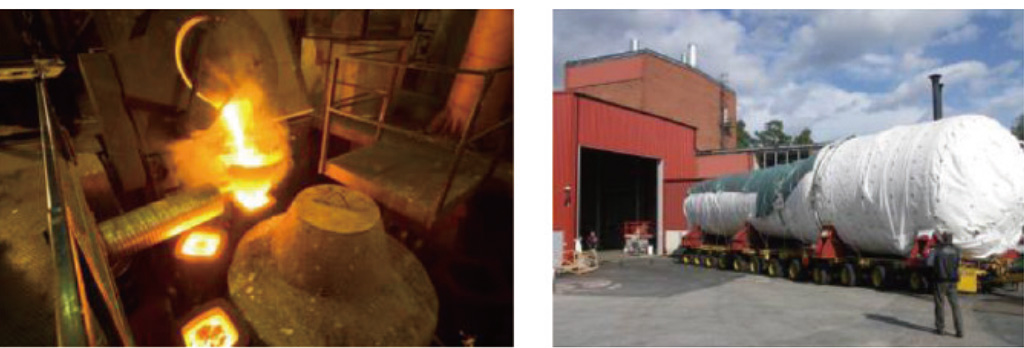

Metal recycle

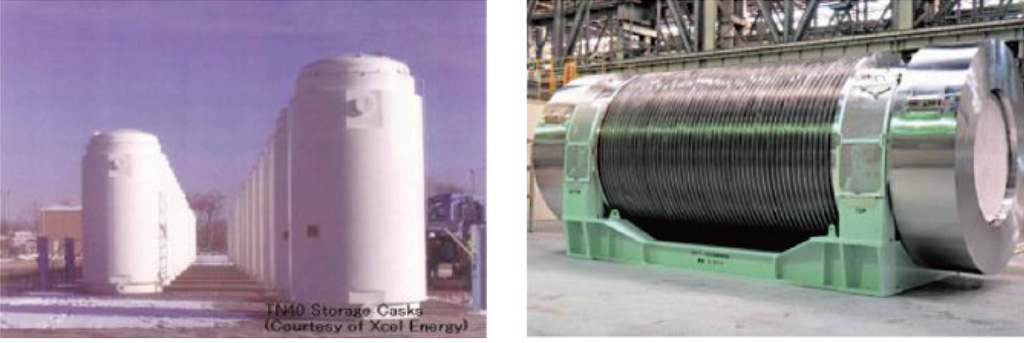

Kobe Steel, as a pioneer of cask in Japan, has manufactured and delivered over 250 large scale forged casks for transport & storage of spent fuel and radioactive wastes generated in nuclear power plants and reprocessing facilities worldwide, with a Transnuclear jointly owned with Orano TN International (France). While a worldleader of steel castings and forgings, we have been supplying reliable high-quality forged casks with our own various material and shaped forgings for the most advanced nuclear power plants, based on our advance technology and capability of world’s large scale forging press (capacity: max. 420t ingot).

Kobe Steel, has also accomplished mass-production of Fuel Channels for BWR fuel assemblies as the first Japanese supplier in the early 1970’s with delivery record of over 50,000 Fuel Channels worldwide.

Technology for production of Boron 10, which is highly enriched boron (more than 96%), was also developed,for the first time in Japan by joint development with Stella Chemifa(Japan)and has delivered enriched boric acid for primary coolant of reactors worldwide.

Kobelco Studsvik Co., Ltd. formed jointly by Kobe Steel and Studsvik AB, will respond to issues concerning the treatment and disposal of radioactive metal waste generated from decommissioned nuclear power plants in Japan.